How To Test Capacitors With Multimeter?

Set the multimeter to read in the high ohms region, between 10k and 1m ohms, to test the capacitor. Connect the meter leads – Positive probes should be connected toward the capacitor’s positive end, while the negative probe must be connected toward the opposite terminal.

A high-quality capacitor will display an extremely high resistance reading at first and then slowly decrease as it gets charged. Once the capacitor has been completely charged, reading of resistance should be infinity (OL). The reading of resistance must be the same for both terminals.

How Can You Test A Capacitor Using The Digital Multimeter?

A capacitor is made up of two conductive plates separated by an insulating material referred to as a dielectric. When the voltage is applied to the plates, it stores the energy within the electric field created between them.

Capacitors are available in a variety of types, including electrolytic, ceramic tantalum, electrolytic, and film capacitors, all of which serve various functions. Capacity is determined by Farads (F), and the voltage rating of their capacitors is different in accordance with the application.

Safety Precautions

Utilizing electronic components poses some risks, as capacitors hold charges that could cause damage. So, prior to beginning any tests, we recommend taking the following precautions to protect yourself:

- Power Off: Ensure the device you’re testing is fully powered off and disconnected from any power source.

- Charge Capacitors: These capacitors may hold electrical charges when the power is turned off. To avoid shocks, put them in a resistor to deplete the capacitors prior to proceeding.

- Your Personal Protective Equipment (PPE): Be sure to wear proper PPE, including gloves and safety glasses, to ensure your safety during tests.

Test Capacitance using a Digital Multimeter

Step 1: Select the Right Multimeter Setting

In the beginning, you must change your digital multimeter’s settings on the capacitance (F) measurement mode. Certain multimeters have a specific setting for capacitance, whereas others employ the common “diode” or “capacitance” symbol. Check the user manual of your multimeter to determine the right setting.

Step 2: Discharge the Capacitor

As previously mentioned, drain the capacitor by using the resistor to get rid of any stored charge. This will ensure your security during the test.

Step 3: Identify the Capacitor Terminals

Determine your capacitor’s positive (anode) and negative (cathode) terminals. When the capacitor has been in polarization (e.g., electrolytic), the positive terminal is typically longer and is marked with a “+” symbol.

Step 4: Connect the Multimeter Leads

Then, connect the multimeter leads to their appropriate capacitor terminals. The red lead should be placed on the terminal that is positive, and both leads on the terminal that is negative. You must ensure a strong connection to get precise readings.

Step 5: Read the Capacitance Value

When the leads are in place, Your digital multimeter will display the capacitance reading on the screen. When the capacitor has been operating properly, the value should be within its capacitance label. Keep in mind that capacitors are tolerant, and there may be a slight variance.

Testing Capacitors for Short Circuits and Open Circuits

Step 1: Set the Multimeter to Resistance Mode

For this test, you must set your multimeter in resistance (ohms) mode. This allows you to see whether the capacitor has short circuits or circuits that are open.

Step 2: Discharge the Capacitor

Always remove the capacitor in order to make sure you are safe.

Step 3: Connect the Multimeter Leads

Connect the multimeter leads to the capacitor terminals just like you did during the capacitance test.

Step 4: Measure Resistance

A functional capacitor will show a brief period of continuity on the display of the multimeter prior to the value of resistance increasing until it reaches infinity. If the multimeter shows an unchanging low resistance, this indicates an open circuit. On the other hand, an unchanging high resistance indicates that there is an open circuit.

What Can You Tell When The Capacitor Is Damaged?

A capacitor is an important electronic component that stores electric energy. It is composed of two conductive plates separated by an insulating material referred to as a dielectric. Capacitors can store and discharge electrical charges, which makes them vital for smoothing variations in voltage, removing signals, and assisting in the start-up of motors.

The signs of a damaged capacitor

- Leaking or bulging Leaking or Bulging: One of the most evident indicators of a damaged capacitor could be the physical damage it has caused. If you observe an increase in the size of your capacitor or leak a brownish substance, it’s an evident sign that the capacitor is failing. A bulging top indicates excessive pressure inside, whereas leaks indicate internal chemical failure.

- Electrolyte Crystallization: A few capacitors, specifically electrolytic capacitors, can suffer from crystallization of electrolytes, which can lead to diminished performance. Be aware of white or crusty crystals that form around the terminals of capacitors.

- Electrical Issues: Capacitors that are not working or have failed could cause electrical issues within the circuit. The causes could be flashing lights, overheated devices, or unusual noises.

- A high ESR (Equivalent series resistance): A higher ESR can be a good indicator of a damaged capacitor. A multimeter can be used to determine the ESR, and If it is higher than the specifications of the manufacturer and is not satisfactory, it’s time to consider an upgrade.

- Low Capacitance: When a capacitor’s capacitance is below the value it was designed to have and is below its rated value, it won’t be able to fulfill its purpose effectively. Capacitance measurements using an instrument for measuring capacitance can show the issue.

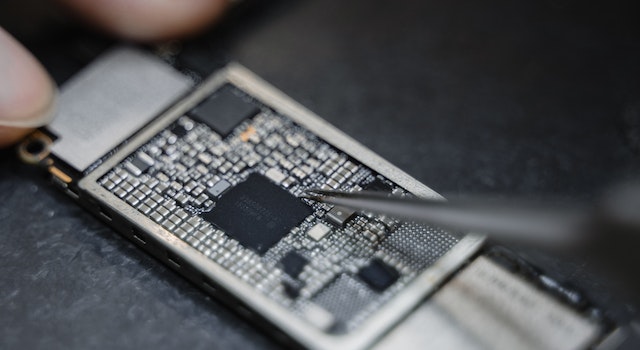

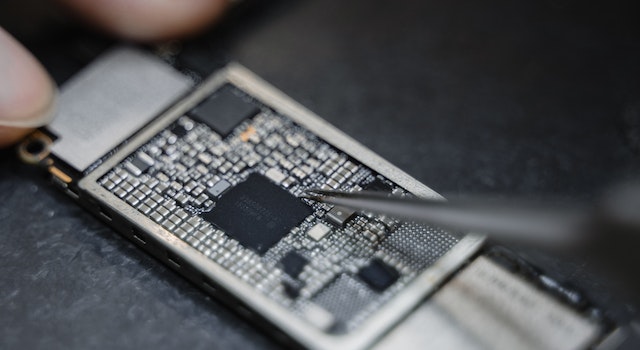

- Failed capacitors on PCBs: In PCBs printed with circuit boards (PCBs), damaged capacitors may show physical damage or leaks, which makes them easy to detect by examination.

The consequences of using a defective capacitor

Continued use of a defective capacitor could result in a variety of negative consequences, including:

- Low Performance: Capacitors that are damaged are unable to store energy and release it effectively, which results in decreased performance of the device or circuit they’re component of.

- Overheating: Components with problems can produce excessive heat and damage other components in the vicinity.

- Circuit instability: A damaged capacitor could result in unstable voltages and fluctuations in the circuit, which can result in unpredictable behavior of the gadget.

- Equipment Damage: In the most severe situations, a defective capacitor could cause irreparable damage or destruction to the device or equipment, leading to expensive repair or replacement.

What is the best way to test the capacitor?

Before you decide if an element is defective, it is possible to conduct a series of tests to determine the condition of the capacitor:

- Checking the visuals: As we mentioned earlier, be sure to carefully examine the capacitor for physical damage, bulging, or leakage.

- Capacitance Test: With the capacitance meter, measure the capacitance of a component and compare it with the nominal value. If you notice a significant difference, this could indicate an issue.

- ESR Test: Use a multimeter that is capable of measuring ESR to see whether it’s within acceptable boundaries.

- Test for Replacement: In certain situations, a simple replacement of the suspect capacitor by a known good capacitor will help determine the source of the issue.

What is the best way to replace a defective capacitor?

If you’ve determined that a capacitor is damaged, then follow these steps to repair it:

The safety first principle is to cut off power from your equipment or device prior to attempting any repair.

- Find the Capacitor: Write the specifications of the capacitor, including capacitance, voltage rating, and polarity. It is important to know this information prior to deciding to purchase the replacement.

- De-soldering to remove the Bad Capacitor: Using a desoldering tool, take the damaged capacitor off the circuit.

- Soldering the new capacitor: Set the capacitor in the right direction and then solder it onto the PCB, ensuring that it has strong and clean connections.

FAQ’s

What type of multimeter should I use to test capacitors?

Answer: For testing capacitors, you’ll need a digital multimeter (DMM) with a capacitance measurement function. Most modern digital multimeters have this feature, which is denoted by a symbol resembling three wavy lines.

How do I prepare the capacitor for testing?

Before testing, ensure the capacitor is discharged to avoid any electrical shock. Use a resistor or a specialized discharge tool across the terminals to remove any stored charge. Once discharged, you can proceed with the testing.

How do I test the capacitance of a capacitor with a multimeter?

To test capacitance, set your multimeter to the capacitance (farad) range. Then, connect the positive lead of the multimeter to the positive terminal of the capacitor and the negative lead to the negative terminal. The multimeter will display the capacitance value. Note that you should choose a multimeter range higher than the expected capacitance for accurate readings.

How can I check if a capacitor is working properly or faulty?

To determine if a capacitor is faulty, you can perform a capacitance test as described earlier. If the capacitance reading deviates significantly from the capacitor’s labeled value (usually exceeding a certain percentage threshold), the capacitor may be faulty and should be replaced.

Can a multimeter test the polarity of a capacitor?

Yes, a multimeter can test the polarity of a capacitor. Set your multimeter to the resistance (ohms) mode. Connect the positive lead to the positive terminal of the capacitor and the negative lead to the negative terminal. Initially, the multimeter will show low resistance (almost zero). After a brief moment, the resistance reading should rise to infinity (∞). If the resistance remains low, the capacitor may be short-circuited and faulty.

How do I check the ESR (Equivalent Series Resistance) of a capacitor using a multimeter?

Not all multimeters can measure ESR directly. ESR testing typically requires specialized equipment. However, some advanced multimeters or capacitor testers might have an ESR measurement function. If your multimeter supports ESR measurement, follow the user manual to activate the ESR mode, and then connect the leads to the capacitor terminals. The multimeter will display the equivalent series resistance value, helping you assess the capacitor’s health.

How To Test Capacitors With Multimeter?

Set the multimeter to read in the high ohms region, between 10k and 1m ohms, to test the capacitor. Connect the meter leads – Positive probes should be connected toward the capacitor’s positive end, while the negative probe must be connected toward the opposite terminal.

A high-quality capacitor will display an extremely high resistance reading at first and then slowly decrease as it gets charged. Once the capacitor has been completely charged, reading of resistance should be infinity (OL). The reading of resistance must be the same for both terminals.

How Can You Test A Capacitor Using The Digital Multimeter?

A capacitor is made up of two conductive plates separated by an insulating material referred to as a dielectric. When the voltage is applied to the plates, it stores the energy within the electric field created between them.

Capacitors are available in a variety of types, including electrolytic, ceramic tantalum, electrolytic, and film capacitors, all of which serve various functions. Capacity is determined by Farads (F), and the voltage rating of their capacitors is different in accordance with the application.

Safety Precautions

Utilizing electronic components poses some risks, as capacitors hold charges that could cause damage. So, prior to beginning any tests, we recommend taking the following precautions to protect yourself:

- Power Off: Ensure the device you’re testing is fully powered off and disconnected from any power source.

- Charge Capacitors: These capacitors may hold electrical charges when the power is turned off. To avoid shocks, put them in a resistor to deplete the capacitors prior to proceeding.

- Your Personal Protective Equipment (PPE): Be sure to wear proper PPE, including gloves and safety glasses, to ensure your safety during tests.

Test Capacitance using a Digital Multimeter

Step 1: Select the Right Multimeter Setting

In the beginning, you must change your digital multimeter’s settings on the capacitance (F) measurement mode. Certain multimeters have a specific setting for capacitance, whereas others employ the common “diode” or “capacitance” symbol. Check the user manual of your multimeter to determine the right setting.

Step 2: Discharge the Capacitor

As previously mentioned, drain the capacitor by using the resistor to get rid of any stored charge. This will ensure your security during the test.

Step 3: Identify the Capacitor Terminals

Determine your capacitor’s positive (anode) and negative (cathode) terminals. When the capacitor has been in polarization (e.g., electrolytic), the positive terminal is typically longer and is marked with a “+” symbol.

Step 4: Connect the Multimeter Leads

Then, connect the multimeter leads to their appropriate capacitor terminals. The red lead should be placed on the terminal that is positive, and both leads on the terminal that is negative. You must ensure a strong connection to get precise readings.

Step 5: Read the Capacitance Value

When the leads are in place, Your digital multimeter will display the capacitance reading on the screen. When the capacitor has been operating properly, the value should be within its capacitance label. Keep in mind that capacitors are tolerant, and there may be a slight variance.

Testing Capacitors for Short Circuits and Open Circuits

Step 1: Set the Multimeter to Resistance Mode

For this test, you must set your multimeter in resistance (ohms) mode. This allows you to see whether the capacitor has short circuits or circuits that are open.

Step 2: Discharge the Capacitor

Always remove the capacitor in order to make sure you are safe.

Step 3: Connect the Multimeter Leads

Connect the multimeter leads to the capacitor terminals just like you did during the capacitance test.

Step 4: Measure Resistance

A functional capacitor will show a brief period of continuity on the display of the multimeter prior to the value of resistance increasing until it reaches infinity. If the multimeter shows an unchanging low resistance, this indicates an open circuit. On the other hand, an unchanging high resistance indicates that there is an open circuit.

What Can You Tell When The Capacitor Is Damaged?

A capacitor is an important electronic component that stores electric energy. It is composed of two conductive plates separated by an insulating material referred to as a dielectric. Capacitors can store and discharge electrical charges, which makes them vital for smoothing variations in voltage, removing signals, and assisting in the start-up of motors.

The signs of a damaged capacitor

- Leaking or bulging Leaking or Bulging: One of the most evident indicators of a damaged capacitor could be the physical damage it has caused. If you observe an increase in the size of your capacitor or leak a brownish substance, it’s an evident sign that the capacitor is failing. A bulging top indicates excessive pressure inside, whereas leaks indicate internal chemical failure.

- Electrolyte Crystallization: A few capacitors, specifically electrolytic capacitors, can suffer from crystallization of electrolytes, which can lead to diminished performance. Be aware of white or crusty crystals that form around the terminals of capacitors.

- Electrical Issues: Capacitors that are not working or have failed could cause electrical issues within the circuit. The causes could be flashing lights, overheated devices, or unusual noises.

- A high ESR (Equivalent series resistance): A higher ESR can be a good indicator of a damaged capacitor. A multimeter can be used to determine the ESR, and If it is higher than the specifications of the manufacturer and is not satisfactory, it’s time to consider an upgrade.

- Low Capacitance: When a capacitor’s capacitance is below the value it was designed to have and is below its rated value, it won’t be able to fulfill its purpose effectively. Capacitance measurements using an instrument for measuring capacitance can show the issue.

- Failed capacitors on PCBs: In PCBs printed with circuit boards (PCBs), damaged capacitors may show physical damage or leaks, which makes them easy to detect by examination.

The consequences of using a defective capacitor

Continued use of a defective capacitor could result in a variety of negative consequences, including:

- Low Performance: Capacitors that are damaged are unable to store energy and release it effectively, which results in decreased performance of the device or circuit they’re component of.

- Overheating: Components with problems can produce excessive heat and damage other components in the vicinity.

- Circuit instability: A damaged capacitor could result in unstable voltages and fluctuations in the circuit, which can result in unpredictable behavior of the gadget.

- Equipment Damage: In the most severe situations, a defective capacitor could cause irreparable damage or destruction to the device or equipment, leading to expensive repair or replacement.

What is the best way to test the capacitor?

Before you decide if an element is defective, it is possible to conduct a series of tests to determine the condition of the capacitor:

- Checking the visuals: As we mentioned earlier, be sure to carefully examine the capacitor for physical damage, bulging, or leakage.

- Capacitance Test: With the capacitance meter, measure the capacitance of a component and compare it with the nominal value. If you notice a significant difference, this could indicate an issue.

- ESR Test: Use a multimeter that is capable of measuring ESR to see whether it’s within acceptable boundaries.

- Test for Replacement: In certain situations, a simple replacement of the suspect capacitor by a known good capacitor will help determine the source of the issue.

What is the best way to replace a defective capacitor?

If you’ve determined that a capacitor is damaged, then follow these steps to repair it:

The safety first principle is to cut off power from your equipment or device prior to attempting any repair.

- Find the Capacitor: Write the specifications of the capacitor, including capacitance, voltage rating, and polarity. It is important to know this information prior to deciding to purchase the replacement.

- De-soldering to remove the Bad Capacitor: Using a desoldering tool, take the damaged capacitor off the circuit.

- Soldering the new capacitor: Set the capacitor in the right direction and then solder it onto the PCB, ensuring that it has strong and clean connections.

FAQ’s

What type of multimeter should I use to test capacitors?

Answer: For testing capacitors, you’ll need a digital multimeter (DMM) with a capacitance measurement function. Most modern digital multimeters have this feature, which is denoted by a symbol resembling three wavy lines.

How do I prepare the capacitor for testing?

Before testing, ensure the capacitor is discharged to avoid any electrical shock. Use a resistor or a specialized discharge tool across the terminals to remove any stored charge. Once discharged, you can proceed with the testing.

How do I test the capacitance of a capacitor with a multimeter?

To test capacitance, set your multimeter to the capacitance (farad) range. Then, connect the positive lead of the multimeter to the positive terminal of the capacitor and the negative lead to the negative terminal. The multimeter will display the capacitance value. Note that you should choose a multimeter range higher than the expected capacitance for accurate readings.

How can I check if a capacitor is working properly or faulty?

To determine if a capacitor is faulty, you can perform a capacitance test as described earlier. If the capacitance reading deviates significantly from the capacitor’s labeled value (usually exceeding a certain percentage threshold), the capacitor may be faulty and should be replaced.

Can a multimeter test the polarity of a capacitor?

Yes, a multimeter can test the polarity of a capacitor. Set your multimeter to the resistance (ohms) mode. Connect the positive lead to the positive terminal of the capacitor and the negative lead to the negative terminal. Initially, the multimeter will show low resistance (almost zero). After a brief moment, the resistance reading should rise to infinity (∞). If the resistance remains low, the capacitor may be short-circuited and faulty.

How do I check the ESR (Equivalent Series Resistance) of a capacitor using a multimeter?

Not all multimeters can measure ESR directly. ESR testing typically requires specialized equipment. However, some advanced multimeters or capacitor testers might have an ESR measurement function. If your multimeter supports ESR measurement, follow the user manual to activate the ESR mode, and then connect the leads to the capacitor terminals. The multimeter will display the equivalent series resistance value, helping you assess the capacitor’s health.