How To Test A Capacitor With A Multimeter?

Here are the steps for the best way to check a capacitor using a multimeter.

- The capacitor should be discharged: This is a must to be done prior to beginning testing capacitors since they can retain charges even after being disconnected from electricity. It is possible to discharge capacitors by putting a resistor on their terminals. A resistor can work for the majority of capacitors.

- Adjust the multimeter to the resistivity (O) option.

- Connect the probes of the multimeter to the capacitor’s terminals: The positive probe must attach to the positive end of the capacitor, while the negative probe must be attached to its negative terminal.

- Take note of the multimeter reading: A good capacitor will begin with a low resistance and then increase until it reaches infinity. If the reading of resistance remains low or the multimeter displays an open line reading, that means the capacitor is damaged.

- Repeat the test with the second end of the capacitor: This will help identify any short circuits that could be present.

What Is The Best Way To Check An AC Capacitor Using A Multimeter?

We will guide you through the procedure of conducting a test on the condition of an AC capacitor using a multimeter. A damaged capacitor could cause many issues with your AC system, so it’s important to know how to spot and properly test them. At the end of this post, you’ll have been equipped with the necessary knowledge to solve and identify problems with capacitors and ensure optimal performance from your air conditioning unit.

Understanding AC Capacitors

Before getting into the testing process, let’s look at what an AC capacitor does and what its importance is within the AC system. AC capacitors can be described as electrical parts that store energy and release it to assist in starting and running the motors of your air conditioning. There are two primary kinds of AC capacitors: those that start and those that run.

- Start Capacitor: The capacitor supplies the additional torque required to start an AC motor. It’s only active during the process of starting and then removed from the circuit.

- Run Capacitor: The run capacitor, in contrast, is always in operation during the entire operation of the AC by continuously supplying the electrical phase shift that is essential for the highest motor performance.

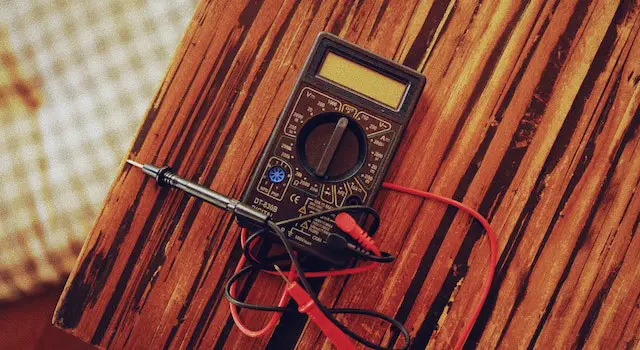

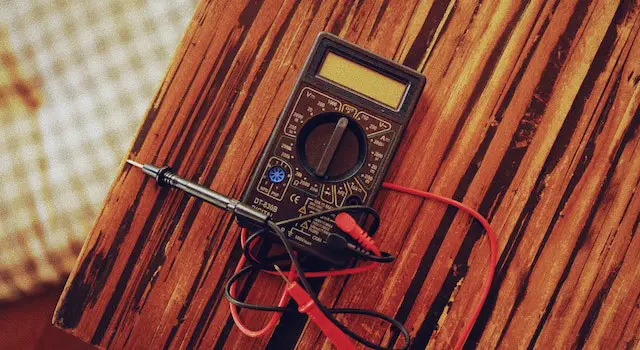

Tools You’ll Need

- For testing the performance of an AC capacitor, you’ll require the following equipment:

- The flexible multimeter can measure resistance, capacitance, and voltage, which allows you to pinpoint any problems that may be affecting the capacitor.

- Equipment for safety: Always put the emphasis on security when handling electrical components. Make sure you wear safety glasses and protective gloves.

Step-by-Step Guide to Testing an AC Capacitor

Follow these steps with care to test your capacitor for AC:

Step 1: Safety First

Before you begin any electrical tests, Before you begin any electrical testing, turn off the power source to the AC unit. Find your main circuit breaker and switch off the circuit that is connected to it.

Step 2: Discharge the Capacitor

Even when the power is off, capacitors may contain an electrical charge, which could be hazardous. To remove the capacitor, you must use an insulated screwdriver fitted with a rubber handle. The connections of the capacitor allow any charge that remains to be released.

Step 3: Access the Capacitor

The next step is to gain access to the capacitor. In accordance with the model of your AC, you may need to remove an enclosure or panel in order to access the capacitor. Be aware and consult the guidelines of the manufacturer for your particular model.

Step 4: Identify the Capacitor Terminals

The majority of AC capacitors come with two terminals. You should be able to identify them and take an outline of their locations for reconnection that is correct in the future.

Step 5: Set the Multimeter

Change your multimeter’s settings to the capacitor setting (usually indicated using the symbol “C”). If your multimeter is equipped with an auto-range function, turn it on. it.

Step 6: Test the Capacitance

Place the multimeter probes on the appropriate terminals of the capacitor. Make sure there is a proper link between the probes and the terminals. The multimeter will show its capacitance measurement. Then, compare this number to the capacitance of the capacitor, which is typically found on its label.

Step 7: Check for Discrepancies

In the event that your measured capacitor differs significantly from the nominal capacitance, this could be a sign of an inefficient capacitor that requires replacement.

Step 8: Testing for Continuity

Then, switch the multimeter on to the setting for resistance (usually indicated with the letter “O”). Put one probe on each of the capacitor’s connections. The multimeter should show the capacitor for a short period of time with no interruption, after which the reading will return to an infinite resistance. This means that the capacitor is operating in the correct manner.

Step 9: Testing for Short Circuits

Change the multimeter’s voltage setting (usually represented using the sign “V”). Be aware of the capacitor being charged, and apply the probe on one end and another probe to the opposite terminal. If the multimeter displays an increase in voltage but then goes to zero, it indicates an unbalanced circuit inside the capacitor, which indicates the need to replace it.

Step 10: Reinstall the Capacitor

After confirming the capacitor’s functioning, restore it to its original location. Make sure to secure any covers or panels that were removed in the process.

Step 11: Restore Power and Test

The power supply is turned back to the main circuit panel for the breaker. Turn on the AC unit and track its performance to make sure the issue is resolved.

What Are The Indicators Of A Damaged AC Capacitor?

Before we look into the symptoms of a defective AC capacitor, it’s important to know its purpose. A capacitor in the AC system stores electric energy and then releases it to start the motor of the compressor. The compressor is then responsible for compressing the refrigerant and facilitating its cooling. Capacitors are of various kinds, comprising start capacitors as well as run capacitors. Each serves specific functions in the system.

The Telltale Signs of a Bad AC Capacitor

Diminished Cooling Performance

An obvious sign of a damaged AC capacitor is a significant reduction in cooling efficiency. If you notice that your AC isn’t able to keep the desired temperature or takes a long time to cool your space, a damaged capacitor may be at fault. A weak capacitor can hinder the compressor’s capability to work effectively, which results in inadequate cooling.

Frequent System Cycling

A damaged AC capacitor could cause a periodic system cycle where the air conditioner is turned off and on quickly. This erratic cycling places excessive strain on the system and can reduce the efficiency of its energy use. If you observe your AC system acting this way, you should investigate the condition of your capacitor.

Unusual Noises

A damaged AC capacitor could produce odd sounds when it is cooling or operating. There could be the sound of humming or clicking, which could be a sign of an electrical problem within the capacitor. The unusual sounds are a red flag and ought to prompt you to have your AC unit checked by a qualified technician.

Bulging or Leaking Capacitor

A close examination of the capacitor may occasionally reveal indications of trouble. If you see an overflowing or bulging capacitor, this is an obvious indicator of a problem. It is an indication of pressure buildup inside, and leakage may result from an issue with the casing of the capacitor. In both cases, prompt intervention is required to avoid any further damage.

Burning Smell

A strong or burned smell emanating from your AC could indicate a failed AC capacitor. In the event of electrical issues, overheating in the capacitor may create this distinctive odor. In the absence of this smell, it can cause more serious damage, so we suggest switching off the unit before calling an expert HVAC technician to inspect and repair it.

AC Unit Doesn’t Start

In the event of a catastrophe, in the worst-case scenario, a damaged AC capacitor could cause the cooling process to kick in. If the capacitor isn’t able to provide the needed electric charging to the motor of the compressor, the AC unit will not turn on in any way. This is a major issue that requires immediate attention from an experienced technician.

Causes of AC Capacitor Failure

Understanding the causes that could lead to AC capacitor failure will aid in taking preventive steps to avoid problems like this later on. The most common causes are:

Age and Wear

As time passes, AC capacitors naturally wear out from constant use and exposure to temperature fluctuations. Regular maintenance can extend their lifespan; however, at some point, they’ll need to be replaced.

Power Surges

Electrical power surges, such as those caused by lightning strikes or grid fluctuations, can overload the capacitor and cause failure.

Overloading

When the AC unit is operating on a small capacitor or is subjected to high electrical demands, it could be overloaded and end up failing early.

Poor Maintenance

Inadequate maintenance, which includes cleaning and checking your AC unit, may lead to the failure of a capacitor.

Prevention and Maintenance

To ensure that the AC capacitor is in tip-top condition and to avoid sudden failures, we suggest the following preventive steps:

Regular Professional Maintenance

Make sure you schedule regular maintenance visits with a certified HVAC technician. They will examine and repair your cooling system and check the condition of your capacitor.

Prompt Repairs

When you first notice an issue with your capacitor, you should immediately begin getting professional repair assistance. A quick fix will help you avoid costly repairs later on.

Surge Protection

Install surge protectors on the AC unit to guard against power surges.

Proper Sizing

Make sure that you ensure that your AC system’s capacitor is adequate for the power requirements of your system.

What Happens When An AC Capacitor Is Damaged?

Before we look into the consequences of a failing AC capacitor, we must first be aware of the role played by capacitors in the AC system. AC capacitors are vital components that are responsible for storing and then releasing electricity. They are used in conjunction with the compressor and fan motor to ensure smooth and efficient performance of the AC unit.

There are generally two kinds of capacitors in an AC system. The first is the start capacitor, which supplies an initial surge of energy that helps start the motor, as well as the run capacitor, which continuously provides energy to ensure that the motor runs efficiently.

Symptoms of a Failed AC Capacitor

We now have knowledge regarding AC capacitors; we can look at the indicators that can indicate the possibility of failure of the capacitor:

- No Cool Air: The most obvious indicator of a failed capacitor is if your AC blasts warm air but does not provide the coolness you’d like to experience.

- Frequent System Cycles: A damaged capacitor could cause your air conditioner to shut off and turn on more frequently than normal, resulting in an inefficient cooling system and higher power consumption.

- Unusual Sounds: You could detect strange buzzing, humming, or clicking sounds through your unit’s AC. These sounds could be the result of a defective capacitor.

- AC Unit won’t turn on: If your AC system is unable to turn on regardless of your efforts, a damaged capacitor may be the cause.

- Circuit Breakers that have been tripped: A capacitor that is in trouble may draw a lot of current, which causes circuit breakers to frequently trip.

- Physical Damage that is visible: The capacitor can display obvious signs of damage, like bulging or leaks. If you spot any of these indicators, it is crucial to take action immediately.

The Dangers of Ignoring a Failing Capacitor

Neglecting the signs of a damaged AC capacitor could lead to an array of issues that could seriously impact the efficiency of your air conditioner and even your comfort. Here are some possible dangers of ignoring a damaged capacitor:

Compressor Damage

A defective capacitor can cause the compressor, which is the central component of an AC unit, to function under a lot of pressure. In time, this extra stress can cause the compressor to fail, which can be costly and difficult to repair.

Reduced Energy Efficiency

When capacitors fail to function, your AC system will have to work harder to compensate, leading to lower energy efficiency. This decrease in efficiency not only adds to the cost of energy but additionally puts excessive strain on other parts, reducing their life span.

Complete System Breakdown

If a capacitor that is failing is not addressed for a prolonged period, it could cause significant damage to the whole AC unit, which could lead to an entire system breakdown. This could require a complete repair of your HVAC system, which is a major cost.

Emergency Repairs

The failure of capacitors usually happens at the most unexpected times, like during hot summer days. Repairs for emergencies can be expensive, difficult to schedule quickly, and leave you without cooling in hot weather.

What to Do When You Suspect a Failed AC Capacitor?

If you suspect that your AC capacitor may be in trouble based on the signs described above, it’s important to act fast. These are the steps you need to take:

- Shut off the AC: Turn off the AC unit as quickly as you can to avoid harm and potentially dangerous situations.

- Consult HVAC Experts: Call an experienced HVAC expert to identify the problem accurately and make the needed repairs.

- Repairing a Capacitor: In the event that a damaged capacitor is found, get the capacitor replaced by a trained technician. Avoid making DIY rerepairs,s the work with electrical components could be risky if you are not properly trained and have the right tools.

- Routine Maintenance: To avoid any future failures of capacitors and increase the long-term durability of your AC unit, plan regular maintenance appointments with your HVAC service provider. Regular inspections will identify possible issues before they turn into major ones.

FAQ’s

What type of multimeter do I need to test a capacitor?

You can use a digital multimeter (DMM) with a capacitance measurement feature to test a capacitor accurately. Ensure your multimeter can measure capacitance in the range you need.

How do I prepare the capacitor for testing?

Before testing, ensure the capacitor is discharged. To do this, short-circuit the terminals using a wire or a resistor. Once discharged, disconnect the capacitor from the circuit to avoid interference.

How do I test a capacitor’s capacitance with a multimeter?

Set your multimeter to the capacitance (farad) mode. Connect the capacitor’s terminals to the corresponding multimeter leads, observing proper polarity. The multimeter will display the capacitance value, which should be close to the capacitor’s labeled rating.

Can I test a capacitor in-circuit?

In most cases, testing capacitors in-circuit is not accurate due to the surrounding components. It’s best to remove the capacitor from the circuit for a reliable measurement.

How can I test a capacitor for a short circuit or open circuit?

Set your multimeter to the resistance mode (ohms). For testing a short circuit, connect the leads to the capacitor terminals. If the multimeter shows very low resistance (close to zero ohms), the capacitor has a short. For testing an open circuit, repeat the process, and if the multimeter shows infinite resistance (OL or open circuit), the capacitor is open.

How do I test a capacitor’s leakage current?

To test for leakage current, set your multimeter to the DC current measurement mode and place it in series with the capacitor (make sure to connect it properly). A small amount of current is expected due to the inherent leakage of capacitors. If the leakage current is significantly high, the capacitor might be faulty and needs replacement.

How To Test A Capacitor With A Multimeter?

Here are the steps for the best way to check a capacitor using a multimeter.

- The capacitor should be discharged: This is a must to be done prior to beginning testing capacitors since they can retain charges even after being disconnected from electricity. It is possible to discharge capacitors by putting a resistor on their terminals. A resistor can work for the majority of capacitors.

- Adjust the multimeter to the resistivity (O) option.

- Connect the probes of the multimeter to the capacitor’s terminals: The positive probe must attach to the positive end of the capacitor, while the negative probe must be attached to its negative terminal.

- Take note of the multimeter reading: A good capacitor will begin with a low resistance and then increase until it reaches infinity. If the reading of resistance remains low or the multimeter displays an open line reading, that means the capacitor is damaged.

- Repeat the test with the second end of the capacitor: This will help identify any short circuits that could be present.

What Is The Best Way To Check An AC Capacitor Using A Multimeter?

We will guide you through the procedure of conducting a test on the condition of an AC capacitor using a multimeter. A damaged capacitor could cause many issues with your AC system, so it’s important to know how to spot and properly test them. At the end of this post, you’ll have been equipped with the necessary knowledge to solve and identify problems with capacitors and ensure optimal performance from your air conditioning unit.

Understanding AC Capacitors

Before getting into the testing process, let’s look at what an AC capacitor does and what its importance is within the AC system. AC capacitors can be described as electrical parts that store energy and release it to assist in starting and running the motors of your air conditioning. There are two primary kinds of AC capacitors: those that start and those that run.

- Start Capacitor: The capacitor supplies the additional torque required to start an AC motor. It’s only active during the process of starting and then removed from the circuit.

- Run Capacitor: The run capacitor, in contrast, is always in operation during the entire operation of the AC by continuously supplying the electrical phase shift that is essential for the highest motor performance.

Tools You’ll Need

- For testing the performance of an AC capacitor, you’ll require the following equipment:

- The flexible multimeter can measure resistance, capacitance, and voltage, which allows you to pinpoint any problems that may be affecting the capacitor.

- Equipment for safety: Always put the emphasis on security when handling electrical components. Make sure you wear safety glasses and protective gloves.

Step-by-Step Guide to Testing an AC Capacitor

Follow these steps with care to test your capacitor for AC:

Step 1: Safety First

Before you begin any electrical tests, Before you begin any electrical testing, turn off the power source to the AC unit. Find your main circuit breaker and switch off the circuit that is connected to it.

Step 2: Discharge the Capacitor

Even when the power is off, capacitors may contain an electrical charge, which could be hazardous. To remove the capacitor, you must use an insulated screwdriver fitted with a rubber handle. The connections of the capacitor allow any charge that remains to be released.

Step 3: Access the Capacitor

The next step is to gain access to the capacitor. In accordance with the model of your AC, you may need to remove an enclosure or panel in order to access the capacitor. Be aware and consult the guidelines of the manufacturer for your particular model.

Step 4: Identify the Capacitor Terminals

The majority of AC capacitors come with two terminals. You should be able to identify them and take an outline of their locations for reconnection that is correct in the future.

Step 5: Set the Multimeter

Change your multimeter’s settings to the capacitor setting (usually indicated using the symbol “C”). If your multimeter is equipped with an auto-range function, turn it on. it.

Step 6: Test the Capacitance

Place the multimeter probes on the appropriate terminals of the capacitor. Make sure there is a proper link between the probes and the terminals. The multimeter will show its capacitance measurement. Then, compare this number to the capacitance of the capacitor, which is typically found on its label.

Step 7: Check for Discrepancies

In the event that your measured capacitor differs significantly from the nominal capacitance, this could be a sign of an inefficient capacitor that requires replacement.

Step 8: Testing for Continuity

Then, switch the multimeter on to the setting for resistance (usually indicated with the letter “O”). Put one probe on each of the capacitor’s connections. The multimeter should show the capacitor for a short period of time with no interruption, after which the reading will return to an infinite resistance. This means that the capacitor is operating in the correct manner.

Step 9: Testing for Short Circuits

Change the multimeter’s voltage setting (usually represented using the sign “V”). Be aware of the capacitor being charged, and apply the probe on one end and another probe to the opposite terminal. If the multimeter displays an increase in voltage but then goes to zero, it indicates an unbalanced circuit inside the capacitor, which indicates the need to replace it.

Step 10: Reinstall the Capacitor

After confirming the capacitor’s functioning, restore it to its original location. Make sure to secure any covers or panels that were removed in the process.

Step 11: Restore Power and Test

The power supply is turned back to the main circuit panel for the breaker. Turn on the AC unit and track its performance to make sure the issue is resolved.

What Are The Indicators Of A Damaged AC Capacitor?

Before we look into the symptoms of a defective AC capacitor, it’s important to know its purpose. A capacitor in the AC system stores electric energy and then releases it to start the motor of the compressor. The compressor is then responsible for compressing the refrigerant and facilitating its cooling. Capacitors are of various kinds, comprising start capacitors as well as run capacitors. Each serves specific functions in the system.

The Telltale Signs of a Bad AC Capacitor

Diminished Cooling Performance

An obvious sign of a damaged AC capacitor is a significant reduction in cooling efficiency. If you notice that your AC isn’t able to keep the desired temperature or takes a long time to cool your space, a damaged capacitor may be at fault. A weak capacitor can hinder the compressor’s capability to work effectively, which results in inadequate cooling.

Frequent System Cycling

A damaged AC capacitor could cause a periodic system cycle where the air conditioner is turned off and on quickly. This erratic cycling places excessive strain on the system and can reduce the efficiency of its energy use. If you observe your AC system acting this way, you should investigate the condition of your capacitor.

Unusual Noises

A damaged AC capacitor could produce odd sounds when it is cooling or operating. There could be the sound of humming or clicking, which could be a sign of an electrical problem within the capacitor. The unusual sounds are a red flag and ought to prompt you to have your AC unit checked by a qualified technician.

Bulging or Leaking Capacitor

A close examination of the capacitor may occasionally reveal indications of trouble. If you see an overflowing or bulging capacitor, this is an obvious indicator of a problem. It is an indication of pressure buildup inside, and leakage may result from an issue with the casing of the capacitor. In both cases, prompt intervention is required to avoid any further damage.

Burning Smell

A strong or burned smell emanating from your AC could indicate a failed AC capacitor. In the event of electrical issues, overheating in the capacitor may create this distinctive odor. In the absence of this smell, it can cause more serious damage, so we suggest switching off the unit before calling an expert HVAC technician to inspect and repair it.

AC Unit Doesn’t Start

In the event of a catastrophe, in the worst-case scenario, a damaged AC capacitor could cause the cooling process to kick in. If the capacitor isn’t able to provide the needed electric charging to the motor of the compressor, the AC unit will not turn on in any way. This is a major issue that requires immediate attention from an experienced technician.

Causes of AC Capacitor Failure

Understanding the causes that could lead to AC capacitor failure will aid in taking preventive steps to avoid problems like this later on. The most common causes are:

Age and Wear

As time passes, AC capacitors naturally wear out from constant use and exposure to temperature fluctuations. Regular maintenance can extend their lifespan; however, at some point, they’ll need to be replaced.

Power Surges

Electrical power surges, such as those caused by lightning strikes or grid fluctuations, can overload the capacitor and cause failure.

Overloading

When the AC unit is operating on a small capacitor or is subjected to high electrical demands, it could be overloaded and end up failing early.

Poor Maintenance

Inadequate maintenance, which includes cleaning and checking your AC unit, may lead to the failure of a capacitor.

Prevention and Maintenance

To ensure that the AC capacitor is in tip-top condition and to avoid sudden failures, we suggest the following preventive steps:

Regular Professional Maintenance

Make sure you schedule regular maintenance visits with a certified HVAC technician. They will examine and repair your cooling system and check the condition of your capacitor.

Prompt Repairs

When you first notice an issue with your capacitor, you should immediately begin getting professional repair assistance. A quick fix will help you avoid costly repairs later on.

Surge Protection

Install surge protectors on the AC unit to guard against power surges.

Proper Sizing

Make sure that you ensure that your AC system’s capacitor is adequate for the power requirements of your system.

What Happens When An AC Capacitor Is Damaged?

Before we look into the consequences of a failing AC capacitor, we must first be aware of the role played by capacitors in the AC system. AC capacitors are vital components that are responsible for storing and then releasing electricity. They are used in conjunction with the compressor and fan motor to ensure smooth and efficient performance of the AC unit.

There are generally two kinds of capacitors in an AC system. The first is the start capacitor, which supplies an initial surge of energy that helps start the motor, as well as the run capacitor, which continuously provides energy to ensure that the motor runs efficiently.

Symptoms of a Failed AC Capacitor

We now have knowledge regarding AC capacitors; we can look at the indicators that can indicate the possibility of failure of the capacitor:

- No Cool Air: The most obvious indicator of a failed capacitor is if your AC blasts warm air but does not provide the coolness you’d like to experience.

- Frequent System Cycles: A damaged capacitor could cause your air conditioner to shut off and turn on more frequently than normal, resulting in an inefficient cooling system and higher power consumption.

- Unusual Sounds: You could detect strange buzzing, humming, or clicking sounds through your unit’s AC. These sounds could be the result of a defective capacitor.

- AC Unit won’t turn on: If your AC system is unable to turn on regardless of your efforts, a damaged capacitor may be the cause.

- Circuit Breakers that have been tripped: A capacitor that is in trouble may draw a lot of current, which causes circuit breakers to frequently trip.

- Physical Damage that is visible: The capacitor can display obvious signs of damage, like bulging or leaks. If you spot any of these indicators, it is crucial to take action immediately.

The Dangers of Ignoring a Failing Capacitor

Neglecting the signs of a damaged AC capacitor could lead to an array of issues that could seriously impact the efficiency of your air conditioner and even your comfort. Here are some possible dangers of ignoring a damaged capacitor:

Compressor Damage

A defective capacitor can cause the compressor, which is the central component of an AC unit, to function under a lot of pressure. In time, this extra stress can cause the compressor to fail, which can be costly and difficult to repair.

Reduced Energy Efficiency

When capacitors fail to function, your AC system will have to work harder to compensate, leading to lower energy efficiency. This decrease in efficiency not only adds to the cost of energy but additionally puts excessive strain on other parts, reducing their life span.

Complete System Breakdown

If a capacitor that is failing is not addressed for a prolonged period, it could cause significant damage to the whole AC unit, which could lead to an entire system breakdown. This could require a complete repair of your HVAC system, which is a major cost.

Emergency Repairs

The failure of capacitors usually happens at the most unexpected times, like during hot summer days. Repairs for emergencies can be expensive, difficult to schedule quickly, and leave you without cooling in hot weather.

What to Do When You Suspect a Failed AC Capacitor?

If you suspect that your AC capacitor may be in trouble based on the signs described above, it’s important to act fast. These are the steps you need to take:

- Shut off the AC: Turn off the AC unit as quickly as you can to avoid harm and potentially dangerous situations.

- Consult HVAC Experts: Call an experienced HVAC expert to identify the problem accurately and make the needed repairs.

- Repairing a Capacitor: In the event that a damaged capacitor is found, get the capacitor replaced by a trained technician. Avoid making DIY rerepairs,s the work with electrical components could be risky if you are not properly trained and have the right tools.

- Routine Maintenance: To avoid any future failures of capacitors and increase the long-term durability of your AC unit, plan regular maintenance appointments with your HVAC service provider. Regular inspections will identify possible issues before they turn into major ones.

FAQ’s

What type of multimeter do I need to test a capacitor?

You can use a digital multimeter (DMM) with a capacitance measurement feature to test a capacitor accurately. Ensure your multimeter can measure capacitance in the range you need.

How do I prepare the capacitor for testing?

Before testing, ensure the capacitor is discharged. To do this, short-circuit the terminals using a wire or a resistor. Once discharged, disconnect the capacitor from the circuit to avoid interference.

How do I test a capacitor’s capacitance with a multimeter?

Set your multimeter to the capacitance (farad) mode. Connect the capacitor’s terminals to the corresponding multimeter leads, observing proper polarity. The multimeter will display the capacitance value, which should be close to the capacitor’s labeled rating.

Can I test a capacitor in-circuit?

In most cases, testing capacitors in-circuit is not accurate due to the surrounding components. It’s best to remove the capacitor from the circuit for a reliable measurement.

How can I test a capacitor for a short circuit or open circuit?

Set your multimeter to the resistance mode (ohms). For testing a short circuit, connect the leads to the capacitor terminals. If the multimeter shows very low resistance (close to zero ohms), the capacitor has a short. For testing an open circuit, repeat the process, and if the multimeter shows infinite resistance (OL or open circuit), the capacitor is open.

How do I test a capacitor’s leakage current?

To test for leakage current, set your multimeter to the DC current measurement mode and place it in series with the capacitor (make sure to connect it properly). A small amount of current is expected due to the inherent leakage of capacitors. If the leakage current is significantly high, the capacitor might be faulty and needs replacement.